Wheel loaders are closely used on the development web site. Being such sturdy machines with many makes use of on the jobsite. Not solely can they carry and haul issues away, however they will clear an space of particles and usher in issues like gravel or dust. Whereas these machines are helpful on their very own, the addition of revolutionary expertise has improved their means to assist on the job.

Extra assist is supplied by on-board expertise like weighing help and sensible tires. This expertise permits for improved effectivity and productiveness in addition to simplified operation.

Loading on the Expertise

Wheel loaders are a necessary a part of the jobsite and play a big position in the case of bringing in and exporting payloads. The machines assist load up vehicles and assist make sure that all the things is loaded correctly due to the expert operators. However just a little assist when doing such an necessary job generally is a nice aid to operators even when not completely vital. With wheel loaders, there are many applied sciences which have come out and many that can proceed to return out to make the wheel loader course of extra environment friendly and make the operator’s job just a little bit simpler.  With an on-board tire strain system, operators and contractors can higher keep gasoline effectivity, tire life, operator consolation and machine efficiency, and save time on routine upkeep.Volvo Development Gear

With an on-board tire strain system, operators and contractors can higher keep gasoline effectivity, tire life, operator consolation and machine efficiency, and save time on routine upkeep.Volvo Development Gear

Weighing Help

Weighing help on wheel loaders takes a number of the guessing out of loading. Utilizing a wheel load to fill a truck is made a lot simpler by getting actual weights in every scoop.

“On-board weighing lets you recognize precisely how a lot materials you’re loading, which might scale back or eradicate over- and under-loading,” stated Eric Yeomans, product supervisor — massive wheel loaders at Volvo Development Gear.

It’s necessary to know the exact weight of every load and the way a lot every truck goes to hold. If the load isn’t weight, there might be penalties.

Yeomans stated, “Overloading may end up in pricey fines, and under-loading will increase manufacturing prices. Correct load weight additionally helps gasoline effectivity and helps reduce upkeep prices on account of additional put on and tear.”  It’s necessary to know the exact weight and quantity every truck is ready to carry.Volvo Development Gear

It’s necessary to know the exact weight and quantity every truck is ready to carry.Volvo Development Gear

Weighing help has been round for some time now and might be ignored as a result of it’s not a brand-new innovation however can have extra impression than realized.

Yeomans stated, “On-board weighing offers … enormously scale back errors and enhance earnings.”

Though weighing help isn’t a brand new idea, there are new issues that may come together with it. Weighing scales proceed to enhance and incorporate extra superior choices.

Scott Schmidtgall, product utility specialist at Caterpillar stated, “They’re meant to be on-the-go weighing scales, so the operator would not actually need to alter his working follow in any respect. It is meant to enhance what he is been doing. It is giving him details about what he is shifting and the way that machine is performing and what you are doing.”

Somewhat than taking on the operator’s job, this sort of expertise is best at aiding the operator and permitting them to go house on the finish of the day much less fatigued. Operators are nonetheless the specialists and are important on the jobsite. Weighing help applied sciences are for simply that – help. They’re a software for the operator to make use of to make their job just a little smoother.

“A extra exact and assured operator means not solely higher productiveness but additionally a happier worker,” stated Yeomans.

- Collision prevention

- Auto-leveling

- Machine velocity limits

- Auto-dig

Tire Strain Monitoring

Wheel loaders carry quite a lot of weight and must roll round, supported by a powerful set of tires. On prime of getting sturdy tires, you will need to know that the tire strain is appropriate. There are totally different choices for this sort of expertise obtainable – Volvo has a strain monitoring system that helps operators simply verify the tire strain from proper contained in the cab, for instance.

Tire strain monitoring is a great tool for maintaining wheel loaders secure and well-maintained.Volvo Development Gear

Tire strain monitoring is a great tool for maintaining wheel loaders secure and well-maintained.Volvo Development Gear

“With real-time info on tire strain and temperature proven on an in-cab show, they will make it possible for tires are working throughout the appropriate parameters. If not, they’ll obtain an alert and visible show displaying which tire wants consideration,” stated Yeomans.

Yeomans defined that with an onboarded tire strain checking system, operators and contractors can higher keep gasoline effectivity, tire life, operator consolation, and machine efficiency, and save time on routine upkeep.

Tire strain monitoring is a really useful gizmo for maintaining wheel loaders secure and well-maintained. To make sure that such an necessary a part of the machine is in good situation, having a tire strain monitoring system on board is crucial.

Extra Expertise and Suggestions

Wheel loaders are ceaselessly used on the development jobsite and are seen as an incredible software to finish many alternative duties on the job. Issues like payload weighing, on-board weighing help applications, and tire strain monitoring assist by bettering accuracy, effectivity, and efficiency. These applied sciences assist operators and contractors to watch the efficiency, accuracy, and effectivity of their jobsite. Different technological purposes can work hand in hand with the operators to extend worksite info.

Load Out Monitoring

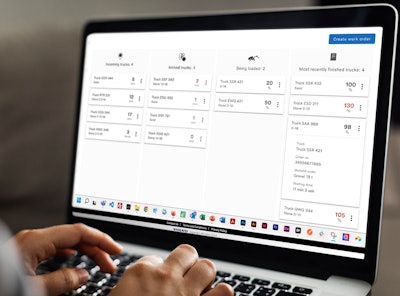

Protecting observe of the masses which can be being put out on a jobsite generally is a large assistance on any jobsite. Companies like Volvo’s Related Load Out can present worksites with a method of monitoring the quantities of every merchandise.

“We … provide a service referred to as Related Load Out that enables corporations to watch and management the overall a great deal of a number of vehicles. A supervisor can arrange a piece order with the focused weights of every materials and the names of the vehicles, after which monitor and observe the fabric that’s being delivered by every truck,” stated Yeomans.  Companies like Volvo’s Related Load Out can present worksites with a method of monitoring the quantities of every product being loaded.Volvo Development Gear

Companies like Volvo’s Related Load Out can present worksites with a method of monitoring the quantities of every product being loaded.Volvo Development Gear

On a building jobsite, it’s essential to concentrate on the precise quantities of every materials wanted for the job and which vehicles are carrying what.

Yeomans stated, “They’ll export knowledge from a flash drive to see each truckload when a selected operator began and completed, what materials they took, and so forth. This helps them plan forward and make the most of their fleet extra effectively to cut back gasoline consumption and emissions.”

Not solely can this service assist with effectivity and discount of emissions nevertheless it additionally will help lower stress ranges and time used to work on administration or to journey.

Bucket Measurement

When optimizing a wheel loader, contemplating the scale of the bucket is a vital step.

Schmidtgall stated, “You need to just be sure you are sizing your bucket and your loader appropriately for the fabric densities that you just’re shifting. So in the event you’re shifting a heavier materials like damp sand vs a lighter materials density like a clear stone; the heavier damp sand would usually represent a smaller bucket.”

The dimensions of the bucket could make an enormous distinction within the productiveness of the machine. Taking weight into consideration helps slender down probably the most environment friendly dimension bucket for the job.

Help expertise cannot solely assist the operator, but additionally scale back fatigue.Caterpillar

Help expertise cannot solely assist the operator, but additionally scale back fatigue.Caterpillar

Some corporations provide specifically sized buckets relying on the fabric or utility vital. Discovering the proper kind of bucket for the fabric can enhance the usefulness of the wheel loader on the jobsite and reduce delays.

“They’re particularly designed for quite a lot of floor situations, so operators have a neater time capturing and delivering materials — which means sooner cycle occasions and fewer gasoline consumption,” stated Yeomans.

Technological Alternatives

Whereas wheel loaders have just a few very helpful choices in the case of assistive expertise, there are much more that may assist with the on a regular basis work course of as nicely. Relying on what an organization wants, many alternatives come up for different useful providers.  Volvo’s Collision Mitigation System helps stop crashes.Volvo Development Gear

Volvo’s Collision Mitigation System helps stop crashes.Volvo Development Gear

Different applied sciences provided embrace:

These and extra can be found from varied corporations to additional profit the operator and worksite group. These sorts of expertise are nice help choices to enhance general perform and workflow for wheel loaders and staff.

Wheel Loader Help

With weighing help, payload weighing, and sensible tire improvements, wheel loaders have been flourishing within the building business. Applied sciences like these present the jobsite with simplified operations and elevated effectivity. Improvements new and outdated play a task within the high quality of the finished job and the convenience with which operators can carry out their duties. This form of revolutionary expertise is a large profit for corporations and staff as it might enhance useability and accuracy.

Many corporations like Caterpillar provide numerous on-board applied sciences used to advance worksite productiveness.Caterpillar

Many corporations like Caterpillar provide numerous on-board applied sciences used to advance worksite productiveness.Caterpillar

Many corporations like Volvo and Caterpillar provide numerous on-board applied sciences used to advance worksite productiveness. Deciding on which improvements to undertake for wheel loaders comes down to non-public necessity and targets. Wheel loader help is one thing that has been round for some time. With it, operators can do high quality work and nonetheless finish the day with much less fatigue than once they work with out help instruments. Wheel loaders are necessary powerhouses for the worksite and helpful for quite a lot of jobs. Because of weighing help, sensible tires, and extra, wheel loaders maintain bettering their providers and helpfulness in many alternative settings.