Concrete slabs kind the spine of numerous industrial and material-handling amenities. Whether or not supporting heavy equipment, mezzanines, pallet racks, or conveyors, a slab should have the ability to bear concentrated masses. But, too typically, inadequate evaluation of load capability ends in pricey over-engineering or catastrophic structural failures.

The excellent news is that many pitfalls related to improper slab evaluation are avoidable. By understanding the important thing elements that have an effect on concrete slab load capability, contractors can keep away from making pricey errors whereas optimizing their assets and holding their staff members secure.

In industrial and warehouse environments, concrete slabs are subjected to dynamic and concentrated masses a lot heavier than typical industrial flooring. Equipment, storage programs, tools, and heavy automobiles exert important strain on comparatively small footprints.

With out a thorough evaluation of slab load capability, amenities face dangers starting from minor cracks and settlement points to extreme structural failures, endangering operational effectivity and employee security.

Key Elements in Concrete Slab Load Evaluation

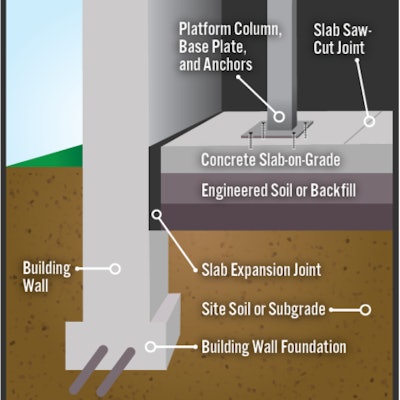

This illustration exhibits the format of a typical warehouse ground and basis. The precise dimensions will range from challenge to challenge.Steele Options Inc.

This illustration exhibits the format of a typical warehouse ground and basis. The precise dimensions will range from challenge to challenge.Steele Options Inc.

Soil Situations & Subgrade Preparation

The inspiration beneath the slab — typically known as the subgrade — is the first help for any concrete construction. Poor soil compaction or inappropriate soil sorts (comparable to clay, natural, or expansive supplies) can result in differential settlement or instability, no matter slab thickness or reinforcement.

For instance, a facility constructed over improperly compacted clay soils may encounter important differential settlement points, inflicting tools misalignment and slab cracking inside a 12 months.

Correct geotechnical analysis and meticulous subgrade preparation — together with compaction, stabilization, and, if obligatory, soil modification — guarantee a stable basis. This step prevents uneven settlement and potential slab failure, in the end making certain structural longevity. Contractors ought to collaborate intently with geotechnical engineers and comply with their steering on compaction ranges and moisture management.

Concrete Thickness & Reinforcement

Figuring out a concrete slab’s optimum thickness and reinforcement is dependent upon the anticipated masses and environmental situations. Thicker slabs and slabs with elevated reinforcement — comparable to rebar, welded wire material, or fiber reinforcement — can normally help heavier masses. They’re additionally much less prone to expertise cracking.

Including extra thickness or extra reinforcement might not resolve the issue.

Let’s take a look at a hypothetical instance: A producing facility initially underestimated the dynamic masses from tools vibration and site visitors, choosing minimal reinforcement. This oversight resulted in widespread slab cracking inside months, necessitating pricey repairs and reinforcements that would have simply been prevented by rising the slab’s thickness or offering supplementary metal reinforcing.

That being stated, including extra thickness or extra reinforcement might not resolve the issue if the concrete design is not the controlling issue. A greater strategy includes cautious evaluation to keep away from inadequate reinforcement on the one hand and pointless prices and useful resource waste on the opposite.

Detailed structural calculations that issue within the actual loading situations, frequency, sort of site visitors (pedestrian, forklift, or heavy automobile), and cargo distribution are important for cost-effective slab design. As well as, elements like temperature fluctuations, publicity to moisture, and corrosive environments should even be thought of.

Joint Proximity & Base Plate Dimension Issues

The proximity of slab joints and the dimensions of apparatus base plates considerably affect slab capability. Slab joints are essential for controlling cracking and accommodating slab motion. However they’re additionally pure factors of weak spot.

When heavy masses are positioned close to joints, stress concentrations can develop, rising the chance of cracking and slab degradation. Correct joint spacing and alignment assist to distribute stress evenly, lowering the chance of localized failures. As an example, inserting heavy storage racks instantly adjoining to joints with out sufficient consideration can lead to speedy deterioration, as seen in warehouses the place slabs develop cracks that propagate shortly and require intensive repairs.

Furthermore, the dimensions and geometry of apparatus base plates or footings additionally play a essential position. Bigger base plates successfully distribute masses over bigger areas, reducing the depth of stress on the slab. Conversely, undersized base plates focus masses, considerably rising the chance of slab cracking or failure.

Frequent Errors in Slab Evaluation & The right way to Keep away from Them

Partaking in early-stage collaboration amongst engineers, architects, house owners, and end-users ensures all related elements influencing slab efficiency are appropriately addressed.

A number of widespread oversights ceaselessly undermine slab load evaluation:

- Ignoring Geotechnical Reviews: Skipping detailed soil evaluations typically ends in improper subgrade preparation, inflicting settlement and cracks. Always remember to conduct and reference thorough geotechnical reviews throughout slab design, and by no means assume uniform soil situations throughout giant areas.

- Underestimating Masses: Failing to precisely calculate static and dynamic masses ends in inadequate slab thickness or insufficient reinforcement. Interact structural engineers early within the design course of to precisely decide load necessities, contemplating each present and future facility wants.

- Neglecting Tools Placement: Misalignment of heavy masses with slab joints or insufficient consideration of base plate dimensions can result in untimely slab failure. Incorporate exact tools placement into preliminary planning levels, making certain load paths align appropriately with designed slab reinforcement and joint layouts.

- Lack of Collaboration: Design selections made in isolation with out cross-disciplinary enter ceaselessly overlook important elements. Foster collaboration amongst geotechnical specialists, structural engineers, facility operators, contractors, and tools suppliers all through the planning course of to make sure cohesive and correct slab design.

- Overlooking Future Facility Utilization: Designing slabs with out contemplating future adjustments in facility format or operational wants can result in inadequately supported slabs as soon as operational situations evolve. All the time incorporate flexibility into design planning to accommodate future tools adjustments or expansions.

Efficient integration of slab load evaluation into the development planning course of begins with a transparent understanding of facility utilization and exact loading situations. Contractors ought to prioritize upfront evaluation, leveraging structural engineering experience to tell design selections. Partaking in early-stage collaboration amongst stakeholders — engineers, architects, house owners, and end-users — ensures all related elements influencing slab efficiency are appropriately addressed.

In the end, by adopting a scientific, knowledgeable strategy, contractors and facility managers can improve the reliability and efficiency of concrete slabs. Integrating complete slab load evaluation reduces dangers, optimizes funding, and ensures operational continuity — supporting safer, extra environment friendly, and extra productive industrial environments.

Briefly, the outdated adage “measure twice, reduce as soon as” doesn’t simply apply to woodworking. It’s additionally a core element of development planning and slab evaluation.