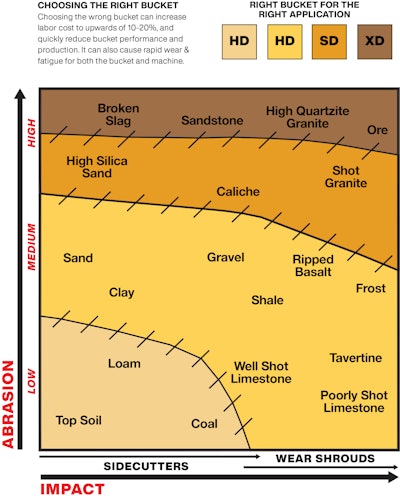

Robust jobs demand robust attachments. However similar to no two job websites are the identical, neither are two excavator buckets. Choosing the improper attachment, per utility, can develop into a expensive mistake, from decreased efficiency to untimely put on of the bucket and machine. The improper attachment will have an effect on your backside line and return on funding. Machine downtime and extra labor can improve prices 10% to twenty%. With cash and equipment at stake, let’s take a look at the elements that go into selecting the best bucket to your wants.

Materials Abrasion and Impression

Materials’s abrasion and influence issue into the kind of bucket that most closely fits your wants. For example, supplies which are low on the abrasive scale with low influence reminiscent of topsoil, loam, and coal are higher dealt with with heavy-duty buckets. Medium abrasive supplies with low to excessive influence reminiscent of sand, clay, gravel, shale, frost, travertine, and limestone are utility additionally effectively fitted to heavy-duty buckets.

For greater abrasive supplies with low to excessive influence reminiscent of excessive silica sand, caliche, and shot granite, these purposes are finest fitted to a severe-duty bucket. Nevertheless, for initiatives with a gradual eating regimen of probably the most abrasive supplies reminiscent of damaged slag, sandstone, excessive quartzite granite, and ore, extreme-duty buckets can be your best option.  Heavy-duty buckets are advisable for trenching in utility work and are nice for numerous contractor conditions.Werk-Brau

Heavy-duty buckets are advisable for trenching in utility work and are nice for numerous contractor conditions.Werk-Brau

The Distinction Between Heavy-Obligation, Extreme-Obligation, and Excessive-Obligation Buckets

AR400 and T1(A514) steels are commonplace materials grades it’s best to guarantee which are utilized in important and high-wear areas in all excavator buckets. Whereas heavy-duty buckets are one of the common excavator bucket kinds, they’re usually chosen when utility circumstances range or will not be well-known. The design goes deeper than simply the kind of metal used. A flat backside permits for simpler load, unload, and backfill, whereas the twin taper/twin backside plate radius permits for extra environment friendly cleanout and fill. A high-strength high channel design prevents flexing and untimely put on. Stacked bosses present extra sturdiness than via bores that are generally used on standard-duty buckets.

Heavy-duty buckets are advisable for trenching in utility work and are nice for numerous contractor conditions. Designed with a thicker backside and aspect put on plates for extra sturdiness, in addition they embrace pre-drilled holes for non-obligatory aspect cutters and shroud protectors. A variety of tooth and shank assemblies are available for set up to make these buckets helpful for a lot of totally different use instances.

Whereas severe-duty excavator buckets make the most of AR400 and T1 metal like heavy-duty buckets, search for severe-duty strains that function high-strength double-wear plates and heavy-duty put on straps, making them ideally suited for greater abrasive circumstances. Their aspect put on plates are 40% thicker for added safety in opposition to abrasion and gouging put on. These buckets are usually 20% heavier than heavy-duty variations however present better sturdiness. The severe-duty leading edge is thicker than its heavy-duty counterpart, and ground-engaging elements are classed as much as accommodate the applying. This leads to elevated abrasion resistance. Extreme-duty buckets have thickened cutter bits and are pre-drilled for non-obligatory bolt-on aspect cutters and shroud safety as effectively.  Choosing the proper bucket for a specific utility will influence the undertaking, backside line and return on funding.Werk-Brau

Choosing the proper bucket for a specific utility will influence the undertaking, backside line and return on funding.Werk-Brau

Excessive-duty excavator buckets function an aggressive dig angle, rugged development of abrasion-resistant metal, and heavy-duty horizontal put on strips, to effectively excavate within the hardest circumstances. Designed for sturdiness and effectiveness, even in brutal circumstances, they are perfect for demolition work, shot rock, abrasive purposes, reasonable prying, and when paired with a thumb — materials dealing with. The aggressive dig angle permits the bucket to tear via the earth and supplies to scoop extra effectively. As well as, tapered aspect plates are engineered to cut back put on and permit for simpler dumping.

Different Excavator Bucket Varieties

If there’s a particular utility, a specialised kind of bucket could also be finest suited versus a heavy-, severe-, or extreme-duty bucket. Ditching and grading buckets as an illustration are designed for cleansing ditches, sloping, grading, and different light-duty ending work. Their shallow depth and compact measurement make working in tight areas straightforward to empty and include solids inside the bucket.

Heavy-penetration buckets, then again, are utilized in heavy abrasive purposes the place breakout power and cycle occasions are vital. In these buckets, the breakout power is maximized as a consequence of decreased tip radius and elevated pin unfold.  If there’s a particular utility, a specialised kind of bucket could also be finest suited versus a heavy-, severe- or extreme-duty bucket.Werk-Brau

If there’s a particular utility, a specialised kind of bucket could also be finest suited versus a heavy-, severe- or extreme-duty bucket.Werk-Brau

Different widespread bucket sorts embrace:

Choosing the proper bucket for a specific utility will influence the undertaking, backside line, and return on funding. No person desires to purchase greater than is required, however shopping for too little might be expensive too. When doubtful about which bucket or attachment is finest to your utility, ask your vendor gross sales rep or the bucket/attachment producer for help – they need to be blissful to help.