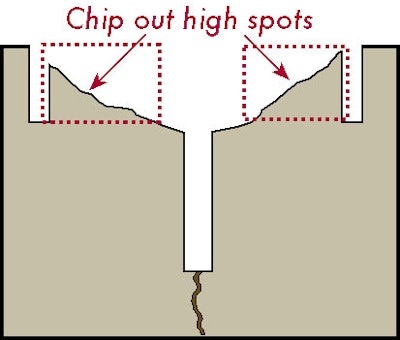

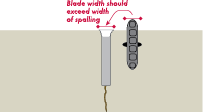

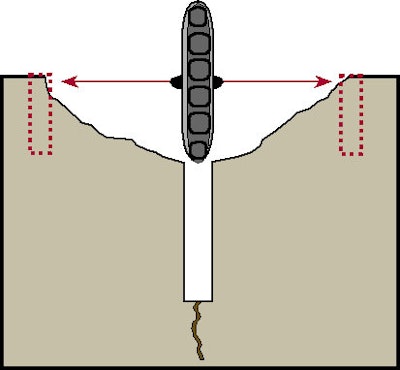

The spalled concrete joint restore preparation and set up course of when utilizing semi-rigid or sand-modified semi-rigid restore supplies just isn’t not like the preliminary joint filling course of. It’s necessary to create clear, vertical edges on the outdoors of the joint restore to permit the restore materials to bond to the joint partitions and to scrub the joint to the nominal depth of the unique sawcut so the restore materials has a structural base of assist.

That is a part of a three-part collection on spalled concrete joint restore. I cowl restore materials kind choice in Half 2 and the causes of concrete joint deterioration in Half 1.

Correct preparation of a joint to be crammed requires that the joint sidewalls be mechanically cleaned utilizing a diamond concrete blade on a stroll behind concrete noticed outfitted with a HEPA mud assortment system. The joint preparation course of ought to take away all dust, particles, noticed minimize laitance, and so forth. and thru mechanically abrading the joint partitions ought to take away any curing compounds or densifiers that flowed into the joint. A clear or “white” concrete alongside the joint partitions is important for correct joint filler adhesion.

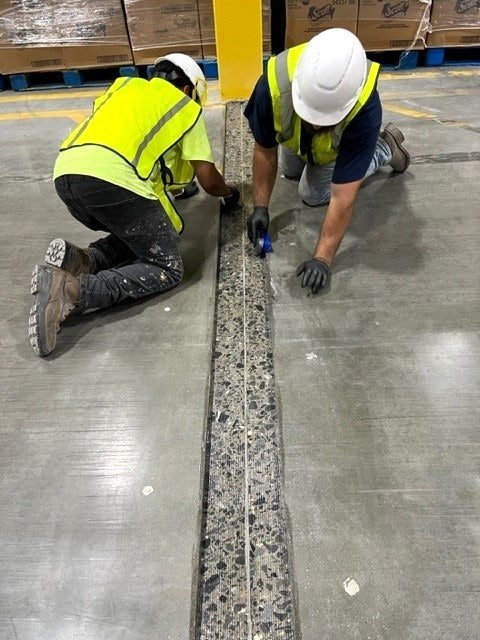

A concrete joint widened for structural restore. Metzger/McGuire

A concrete joint widened for structural restore. Metzger/McGuire

Inherently weakened or “raveled” joint edges from improper noticed reducing timing or faulty noticed blades result in compromised joint edge integrity and a larger chance of joint edge deterioration if not addressed earlier than joint filling. This concern has grow to be extra frequent not too long ago as Sort 1L and different carbon-friendly cement replacements have been rolled out to the concrete trade.

Software of a semi-rigid mixture to a concrete joint for restore. Metzger/McGuire

Software of a semi-rigid mixture to a concrete joint for restore. Metzger/McGuire

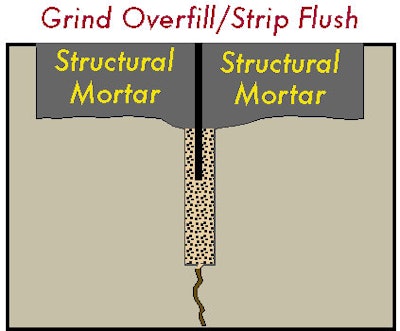

These newly fashioned joint partitions shouldn’t have to run to the total depth of the joint, however most restore materials producers name for a depth of 1/2 – 3/4 in. to permit for the filler to have adequate sidewall contact to bond to and to extra successfully key within the restore materials.

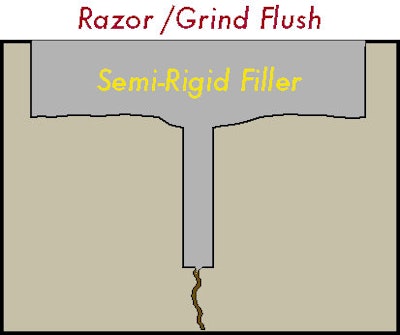

The results of this joint preparation will likely be an elongated “T” form through which to position the filler. As with new joint filler set up, the filler is barely overfilled and the overfill razored or floor off to go away a seamless, flush profile throughout the ground. When utilizing semi-rigid joint fillers — modified or not — there is no such thing as a must re-sawcut the restore to re-honor the present joint, as semi-rigid supplies is not going to restrain slab panels and can nonetheless separate or tear if extreme joint opening happens.

Metzger/McGuire

Metzger/McGuire

In joint repairs with present semi-rigid joint filler put in — corresponding to a joint exhibiting substantial joint filler separation or a joint the place the filler profile was low and uncovered joint edges — it’s typically doable to chop or “mill” out the highest 1/2 in. of the filler and use a number of the preliminary filler as a base for the semi-rigid restore materials. That is solely doable the place the preliminary filler was put in to the right depth, stays intact and effectively bonded to the joint base, and is sufficiently inflexible and comparable in hardness to restore materials.

Metzger/McGuire

Metzger/McGuire

Metzger/McGuire

Metzger/McGuire

Metzger/McGuire

Metzger/McGuire

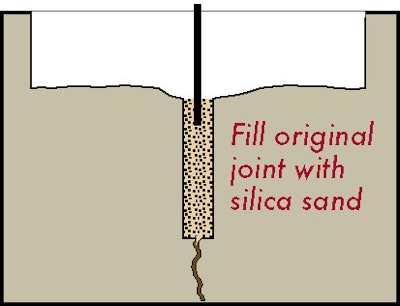

If the structural restore materials flows into the contraction or development joint, it could restrain the motion of the 2 slab panels and may result in tearing or cracking of the panels if motion happens. One of the simplest ways to keep away from that is to fill the present joint with sand as much as the extent of the newly fashioned shelf.

Metzger/McGuire

Metzger/McGuire

As soon as this new joint is minimize, fill it with a semi-rigid filler to guard the restore materials joint edges and make sure the slabs will not be restrained.

It is necessary to acknowledge that on the subject of any constructing facility, the concrete flooring is the literal worksurface for your entire operation. The longer upkeep or restore is deferred, the extra advanced and expensive the repairs grow to be.

So long as flooring have joints, the right remedy and upkeep of these joints will proceed to be important in guaranteeing the long-term serviceability and sturdiness of the ability, its operational productiveness, and its protected operation.