Chalk it as much as a scarcity of coaching, boomers retiring, or the widening expertise deficit amongst accessible candidates-for-hire, however the development trade labor scarcity continues to swamp trade efforts to tackle extra work or full present tasks on time and on schedule.

In keeping with the Related Normal Contractors of America, “91% of development corporations are having a onerous time discovering staff to rent, driving up prices and mission delays.” Related Builders and Contractors share the priority, stating that “the development trade might want to appeal to an estimated 501,000 further staff, on prime of the conventional tempo of hiring in 2024, to satisfy the demand for labor.”

In response, Tools At the moment contacted thought leaders from Caterpillar, Procore, Constructed Robotics and FORT Robotics to discover a number of the methods distant operation and automation applied sciences are serving to to alleviate the development trade labor scarcity.

Feeling the Ache

As we surveyed our panel of specialists, we discovered consensus surrounding the detrimental influence of the labor scarcity throughout the trade. The tight labor market has prompted some corporations to extend compensation or import expertise from exterior the world to workers up. Each are costly choices that ultimately add considerably to the fee prospects pay to maintain their tasks on monitor.

Other than that, many tasks merely get pushed again. The delays can run wherever from six months to a number of years, stoking demand in an already pent up market.

“New laborers coming into the trade these days maintain all of the playing cards,” mentioned Lauren Lee, communications lead and designer at Constructed Robotics, a San Francisco-based startup that sells robotic automation options to the photo voltaic and development industries. “They need safer working circumstances, higher pay and enhanced high quality of life, all of which factors to an inflow of expertise to remodel the best way tasks get performed.”

With out such assist, the strain on crews to carry out and produce will increase the prospect of errors, accidents and rework, none of which is good for enterprise.

“With the intention to crank out the work utilizing the identical variety of individuals and machines,” mentioned Alan Pumklin, Caterpillar product specialist, “you must work smarter and extra effectively. That’s the place expertise could make a big distinction.”

Caterpillar has been a pioneer in development gear automation and autonomy for a few years, most just lately providing its “Cat Command station that may function a number of machines from totally different product households … swap from trenching with an excavator, to utilizing a dozer to backfill, then … selecting up a compactor to wrap issues up.”

The optimist’s view is that, as expertise advances and turns into extra prevalent within the trade, the enchantment of working in development will enhance amongst new recruits.

Expertise will play an essential function in the best way the development trade positions itself in entrance of incoming generations forming the long run workforce.Procore

Expertise will play an essential function in the best way the development trade positions itself in entrance of incoming generations forming the long run workforce.Procore

“There’s a misguided notion that development is one way or the other a fallback profession. A unclean job that no one desires to do. Nothing may very well be farther from the reality,” says Kris Lengieza, vp and world tech evangelist at Procore. “As an trade, we have to spend money on educating our future workforce with the fitting expertise, instruments, and data to hit the bottom working. Expertise will play a major function in how we place ourselves and transfer ahead.”

Expertise as an Antidote

Over time, development website expertise has developed to a spot the place there are extra choices than ever, and the capabilities are solely enhancing. From the web to the cloud to sensible telephones to world satellite tv for pc expertise, advances are making development gear smarter and staff extra productive.

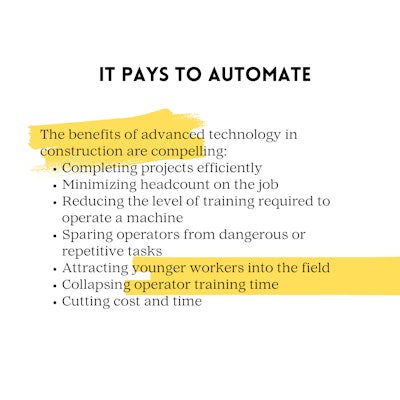

Many authorities infrastructure tasks now name for development gear automation, incentivizing distributors to spend money on “expertise that makes earthmoving and different gear simpler to make use of, captures manufacturing information, or will increase security.” Advances in distant and autonomous development gear expertise characterize a paradigm shift, disrupting the best way tasks are awarded, managed and carried out.

“We’re seeing distant operation from line-of-sight and tele-operation, in addition to job automation for repetitive jobs, assist expert laborers give attention to duties the place their expertise are most wanted,” mentioned Doug Riffle, vp of enterprise improvement at FORT Robotics, which gives applied sciences that allow people and robots to work side-by-side productively and safely. “One distinctive factor that folks like about our distant management choices is that they take their design inspiration from video game-style distant controls. This makes them very simple to be taught and use, and really intuitive for lots of youthful operators,” he mentioned.

In development, robotics and labor saving expertise can make a distinction within the area and the again workplace alike.

“Software program exists that helps decision-makers handle billing, invoicing, and jobsite progress towards contractual agreements and price range projections,” mentioned Lengienza, whose firm, Procore, gives development administration software program for clever danger administration, from preconstruction to closeout. “By integrating the enterprise facet of issues with what’s occurring in the sphere, corporations are in a position to management prices, preserve schedules, and elevate productiveness,” he mentioned. The web result’s that enterprise can do extra with much less.”

Maybe nowhere is the influence felt greater than within the area, the place sensible machines are serving to novice staff carry out at near-veteran proficiency. That is due partly to the evolution of machine management expertise, automating performance based on particular website designs.

Machines geared up with superior expertise options, reminiscent of sensors, screens, and autonomous controls, are in a position to learn digital design info and carry out operations inside extraordinarily tight tolerances. Operators within the cab not have to check schematics on paper or be educated for precision work to get exact outcomes. Even novice operators can produce skilled outcomes.  BUILT Robotics

BUILT Robotics

Utilizing distant operation capabilities, an operator doesn’t even have to be within the cab to impact superior outcomes. From the consolation of a command middle, they’ll remotely information a load bucket by means of an earth pile and come clear with a exact fill each time. The financial system of effort is maximized, whereas materials sources are spared.

The Benefits of Distant Operation and Automation

The use circumstances for distant operation and automation expertise, together with robotics, are nonetheless rising. However wherever operator security, coaching, or morale is anxious, you’ll doubtless discover a dwelling for expertise in your group.

Constructed Robotics sells a completely autonomous robotic pile driver, the RPD 35, that performs 4 capabilities with a single robotic. A crew of two can handle a number of robots, marking GPS floor factors, dragging piles to the situation, driving the piles, then reporting the information. It might take 10 to fifteen crew members to carry out the identical duties with out automation.

Likewise, FORT Robotics just lately helped a Georgia-based landscaping startup beat the labor scarcity utilizing software program and retrofit kits to rework present zero-turn mowers into self-propelled machines. The mowers not solely relieved the bodily pressure staff skilled driving the machines in all sorts of climate, but in addition lowered price, elevated productiveness, and automated the tedious work in order that crew members might give attention to extra worthwhile duties.

Out-of-the-box functions additionally abound as customers experiment with the chances. As an example, augmented and digital actuality are making it doable for operators to view website plans imposed straight over uncooked land. Digital show screens constructed into headsets point out actual markings, guiding earth motion and website preparation.

Onboard AI might be programmed to educate new hires on sure machine functionalities, accelerating time-to-productivity and liberating extremely paid trainers to give attention to different value-added work.

“Certainly one of our stevedore prospects began utilizing our automated cranes to assist unload materials from ships midstream, defending staff from having to maneuver containers onboard or on the dock,” mentioned Pumklin. “It was all performed utilizing robots, remotely managed by an operator sitting in a Cat Command station, managing 4 bots at a time. That’s a 4-to-1 ratio. That’s onerous to beat.”

Get Into the Recreation

Because the labor scarcity lingers, extra opponents are selecting to undertake distant operation and automation expertise. Happily, the method is simpler than you may assume. Retrofit kits and software program upgrades are broadly accessible to satisfy you the place you might be in your journey. The most effective recommendation is to speak to gear distributors and assess your particular wants.

“Ask your individuals what they have to be more practical, then study these processes earlier than you make investments,” mentioned Lengieza, who cautions that expertise isn’t all the time a panacea. “You may’t simply purchase cool stuff and anticipate to maneuver the needle. Suppose when it comes to ROI. For those who can cut back your headcount, time or price on a job by 50%, you’re most likely trying in the fitting place.”

As nicely, think about the influence expertise may need in your present workers. Educate them on some great benefits of expertise and guarantee them that you simply’re not out to interchange them, however to enhance their work life. For those who combine change administration ideas into your plan, you may enhance acceptance and speed up adoption.

“I like to think about it this manner,” says Pumklin from Caterpillar. “If you may function a machine remotely from dwelling as you get well from an harm, that’s a paycheck you may money.”

That’s a top quality of life funding.