The compact tools trade is experiencing a transformative shift as electrification turns into a cornerstone energy supply. Extra unique tools producers (OEMs) are exploring the advantages of changing gas-powered tools towards battery energy. Electrical tools provides a number of compelling benefits together with enhanced sustainability and effectivity, diminished working prices and upkeep and quiet, emissions-free operation.

Nevertheless, there’s a lot to think about with regards to electrification and navigating the method of changing gas-powered tools to battery energy. Electrification is extra than simply changing a conventional inside combustion engine with an electrical energy supply corresponding to a battery. It additionally entails integrating needed parts to create a complete battery system that features parts corresponding to motors and motor controllers. As industries transfer towards extra sustainable applied sciences, electrification is turning into a vital technique for OEMs to stay aggressive and meet regulatory requirements.

Electrical engineering experience wanted

For OEMs, a unique ability set is required in engineering to develop high-performing electrical tools that provides customers the fitting expertise. Electrified tools provides many capabilities, so OEMs want to totally perceive what the interconnected parts of a battery system can do. This can unlock the advantages battery energy can provide to make work simpler, safer and extra environment friendly.

From evaluating battery choices and understanding the vary and runtime of kit to figuring out effectivity beneficial properties and integrating the battery system into tools, there’s a lot that goes into making the swap to electrical energy. Navigating these complexities could be difficult, particularly for small- and mid-sized OEMs. Partnering with electrification consultants may also help with providing engineering help and standardized options to streamline the electrification course of.

By leveraging intensive, first-hand information and expertise, energy software consultants may also help OEMs overcome technical challenges corresponding to energy density, weight distribution and thermal administration. A very good accomplice additionally will assist guarantee compliance with regulatory requirements and handle security issues which can be paramount in new know-how adoption.

Let’s discover the electrification course of and what OEMs ought to anticipate when navigating the electrification journey.

Understanding energy wants

The journey to electrification begins with meticulous preparation and a deep understanding of the appliance’s present energy wants. One of many preliminary steps is making a load profile, which entails assessing the tools’s energy wants and utilization patterns. Understanding the load profile is crucial for figuring out the suitable battery dimension and specs. Components corresponding to capability, voltage and battery chemistry play a crucial function on this decision-making course of, guaranteeing the chosen battery meets the tools’s efficiency necessities.

Creating an correct load profile requires an in depth evaluation of the tools’s operational cycles. This consists of figuring out peak energy calls for, common utilization patterns and potential energy-saving alternatives. Tools used intermittently all through the day could have completely different energy necessities than machines which can be repeatedly working. By precisely mapping these wants, OEMs can choose a battery that gives optimum efficiency with out oversizing or undersizing the ability supply.

As soon as the load profile is established, the following step is correct battery sizing and specification.

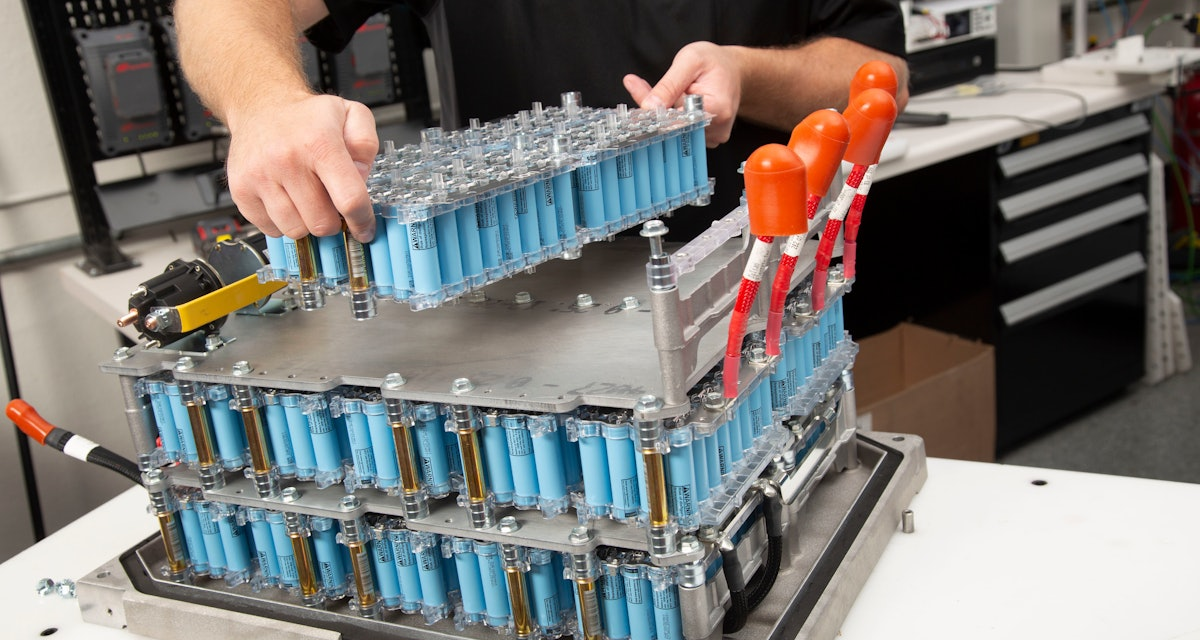

Designing the battery system

Battery know-how has splintered into a number of completely different classes because it has developed through the years. Numerous chemistries corresponding to Lithium-Ion, nickel-metal hydride and lead acid have their very own benefits and limitations. Lithium-Ion batteries, for instance, are identified for his or her excessive vitality density and lengthy cycle life, making them excellent for compact tools. Nevertheless, the selection of battery additionally is dependent upon elements like price, weight and environmental situations. OEMs should weigh these issues to pick probably the most appropriate battery for his or her particular functions.

Engineering help from consultants extends past simply offering a battery to interchange an engine. It consists of complete integration help, guaranteeing the battery system is built-in into the present tools design. This entails modifying tools to accommodate the battery, optimizing the location of parts for steadiness and stability and integrating energy administration techniques that regulate battery utilization and charging.

Engineering help from consultants consists of complete integration help, guaranteeing the battery system is built-in into the present tools design.Briggs & Stratton

Engineering help from consultants consists of complete integration help, guaranteeing the battery system is built-in into the present tools design.Briggs & Stratton

Battery integration and software testing

Integration and software testing are essential levels within the electrification journey. Seamless integration of battery energy into present tools designs requires cautious planning and execution. Software testing entails rigorous assessments underneath varied working situations to make sure the tools’s efficiency meets trade requirements. This consists of testing for sturdiness, effectivity and security.

For instance, compact tools utilized in development should have the ability to stand up to harsh environments, heavy masses and steady operation. Via intensive testing, OEMs can establish potential points, make needed changes and be sure that the electrified tools performs reliably in real-world situations. After the tools has confirmed itself in preliminary trials, OEMs usually will put the machine by way of its paces with area testing to get buyer suggestions on its efficiency and runtime.

The method of changing gas-powered tools to battery energy is multifaceted, involving cautious planning, technical experience and rigorous testing. With the help of electrification consultants, OEMs can navigate this journey and assist guarantee a profitable transition to electrical energy as they appear to supply a aggressive lineup of fuel and electrical tools choices for no matter a buyer could also be in search of.

Looking forward to the longer term

Because the market evolves, OEMs that embrace electrification for his or her automobiles might be well-positioned to fulfill the rising demand for zero-emission options. The adoption of electrical energy isn’t just a development, however a strategic transfer in the direction of a extra sustainable and environment friendly future. By staying forward of technological developments and leveraging the experience of electrification specialists, OEMs can guarantee a clean transition to electrification whereas capitalizing on the chance to supply extra energy decisions to their clients.

Stephen Avery is engineering supervisor — battery functions at Briggs & Stratton.