Hydraulic oils are utilized in many areas of our life, from the telescopic booms of cranes to the management valves in a tractor. These oils are particular as they carry out a selected operate which is exclusive to them. In addition to the common features of an oil, hydraulic oils can transmit energy which actually units them aside. On this article, we are going to take a deeper dive into the world of hydraulic oils, how they can be utilized, ways in which they need to be saved and dealt with and naturally some developments that we’ve seen over the years.

What Are The Features of Hydraulic Oils?

Earlier than going any additional, we should perceive how hydraulic oils operate and the impression that they create for our tools. As per (Pirro, Webster, & Daschner, 2016), the idea of hydraulics revolves across the transmission of drive from one level to a different the place the fluid is the transmitter of this drive. Ideally, that is primarily based off Pascal’s Legislation the place, “The stress utilized to a confined fluid is transmitted undiminished in all instructions and acts with equal drive and at proper angles to them.”

As utilized to hydraulic oils, as soon as a drive is exerted on an oil, the oil can transmit this drive to both assist an actuator flip or cease an excavator from shifting (by braking). That is the transmission of stress, however hydraulic oils may also present the features of diminished put on, prevention of rust and corrosion, discount in put on and friction and an total enchancment in system effectivity.

For anybody who has labored with hydraulic oils, they are going to be aware of the truth that these oils have very tight clearances which requires them to be clear. As they’re transmitting energy by the fluid, having clear hydraulic oil is important, so this movement is just not disrupted. Since the drive would be the identical all through the lubricant, having these tighter clearances permits for extra drive to be output per sq. space on the meant goal with out the contaminants.

General, hydraulics will carry out the common features of an oil however with the additional advantage of the transmission of drive for these purposes. However not all hydraulic oils are created equally and a few have to be particularly designed for specific purposes inside our trade.

Are There Totally different Kinds of Hydraulic Oils?

Much like there being limitless kinds of greases, there are additionally many kinds of hydraulic oils particularly designed for sure methods. Hydraulics comprise of plenty of completely different operations as such, they are going to be known as upon to carry out in numerous purposes. A few of these can embrace being fireplace resistant, biodegradable and even with the ability to additionally act as an engine oil. These properties could be influenced by the kind of base oil used to provide these oils. For instance, fireplace resistant or quickly biodegradable fluids and even specialty hydraulic fluids can use PAOs (Polyalphaolefins), PAGs (Polyalkylglycols), POE (ester oils) or different artificial oils as their base oil.

As per (Mang & Dresel, 2007), hydraulics require particular kinds of components for his or her purposes. A very powerful components for hydraulic oils are:

“Floor energetic components” – For hydraulic oils these could be rust inhibitors, steel deactivators, put on inhibitors, friction modifiers, detergents / dispersants, and so forth.

“Base Oil energetic components” – For hydraulic oils, these could be antioxidants, defoamers, VI Improvers, Pourpoint improvers, and so forth.

Sometimes, the components for hydraulic oils could be broadly classed into these which comprise zinc and ash and people which don’t. Zinc and Ash free oils can symbolize 20-30% of hydraulic oils available on the market and are used for specialty purposes the place the presence of zinc or ash can hamper the performance of the tools.

One such instance is the usage of these oils within the JCB Fastrac 3000 collection for the hydraulic oils. These methods comprise yellow metals which could be simply degraded with the presence of zinc or the filterability of the oil could be impacted because of the presence of water. Therefore, zinc and ash free oils have to be utilized in these situations.

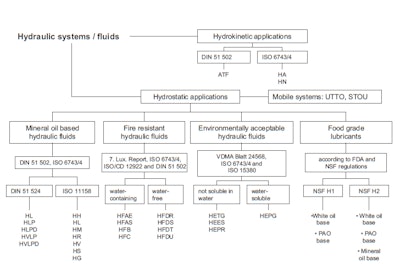

The next exhibits a chart of the kinds of hydraulic fluids as per (Mang & Dresel, 2007) damaged down by hydrokinetic purposes, hydrostatic purposes and cellular methods.

Determine 1: Classifications of hydraulic fluids as per (Mang & Dresel, 2007) Chapter 11, determine 11.9.Strategic Reliability Options Ltd.

Determine 1: Classifications of hydraulic fluids as per (Mang & Dresel, 2007) Chapter 11, determine 11.9.Strategic Reliability Options Ltd.

As seen above, there are various completely different classifications of hydraulic oils. To offer some clarification on the symbols utilized in DIN 51 502 and ISO 6743/4, (Mang & Dresel, 2007) produced this desk.

Determine 2: Classification of mineral oil-based hydraulic fluids as per (Mang & Dresel, 2007), Chapter 11, Desk 11.3.Strategic Reliability Options Ltd.

Determine 2: Classification of mineral oil-based hydraulic fluids as per (Mang & Dresel, 2007), Chapter 11, Desk 11.3.Strategic Reliability Options Ltd.

When hydraulic oil classifications, these classes will come up and it is very important have the ability to perceive what every of those imply in addition to the way it interprets to your system. Sometimes, probably the most widespread are the ISO HM and ISO HV.

The ISO HM refers to oils with improved anti-wear properties used typically hydraulic methods with extremely loaded elements and the place there is a necessity for good water separation working within the vary of -20 to 90°C.

The ISO HV oils are HM oils with components that enhance viscosity-temperature conduct. Ideally, these are utilized in environments that expertise vital adjustments in temperatures, similar to building or marine, between the ranges of -35 to 120°C.

Are Consolidation and Cheaper Hydraulic Oils Worthwhile Concerns?

Given the assorted kinds of hydraulic oils that exist, can all of them be consolidated into one hydraulic oil that may serve the aim for all of the purposes? The quick reply is not any, the longer reply is that if there may be overlap amongst OEM suggestions inside the identical viscosity, then there’s a chance of consolidation. Sometimes, OEMs will present tips on the oils really useful to be used and they need to be sought out for these consolidations as they are going to be extra aware of compatibility points, as nicely.

However, it could imply that the hydraulic storage space of the warehouse has quite a few hydraulic oils. On this case, a correct labelling system must be in place to make sure that the proper oil will get to the proper location. Since these are specialised, utilizing an incorrect oil (or an oil that doesn’t meet the appropriate specification) can lead to disastrous outcomes for the tools particularly for compatibility challenges.

One of the crucial widespread points with hydraulic tools is the existence of leaks. Relying on the applying, some homeowners favor to not repair the leaks and use low-cost hydraulic oil to maintain the tools working. Nevertheless, this isn’t one of the best follow.

When hydraulic oil leaks out into the surroundings, this could be hazardous to the individuals on the location (spills or journeys), tools (skids or contamination) and the surroundings because it was not disposed of correctly. By utilizing low-cost oil, this could additionally harm the tools much more as that oil might not meet the OEM necessities. In these circumstances, extra hurt is being finished to the surroundings and the tools and there could be vital losses financially and operationally.

That is the place the standard of the oil and operations (no leaks) can trump amount (extra volumes of cheaper oil). Until the leaks are fastened, then the quantity of cheaper oil will proceed to extend and there’ll be extra labour prices to always preserve the sump ranges in addition to delays to the challenge.

Due to this fact, the general impression on the effectivity of the hydraulic tools will probably be diminished. Nevertheless, if the leaks are fastened and a high quality hydraulic oil is used, then the machine can function extra effectively, full the assigned tasks and probably even scale back additional labour prices associated to upkeep.

Ideally, consolidation could be achieved so long as the OEM necessities are being fulfilled. Nevertheless, cheaper oil that doesn’t meet the required OEM customary for a selected piece of apparatus is just not a great choice as it will possibly trigger extra hurt than good in the long term.

Storage and Dealing with

Hydraulic methods have smaller clearances than many. As such, it’s crucial that these oils be saved clear and free from any particles. Most hydraulic elements have a required ISO 4406 ranking that must be met to make sure that the oils don’t enable overseas particles to enter as these can simply clog the clearances and trigger the system to cease working.

Chevron Lubricants produced a doc that compiles some ISO 4406 codes for numerous kinds of industrial off freeway tools, which additionally consists of the hydraulic requirements. It famous the really useful ISO Cleanliness for John Deere hydraulic Excavators could be ≤23/21/16, this could be discovered right here (Chevron Lubricants, 2015).

Hydraulic oils must be pre-filtered earlier than being positioned in your tools regardless that there are filters on the within of the tools by lowering the quantity of contamination getting into the system from the onset, you can guarantee an extended life in your hydraulic oil. Hydraulic oils must also be saved in closed containers not these which might be left open to the environment!

Developments in Hydraulic Oils

In accordance with CITATION Fit21 l 1033 (Fitzpatrick & Thom, 2021), the hydraulic oil market was roughly value USD 77.5 billion by the tip of 2021. Cellular hydraulics account for 65% of the market whereas industrial tools represents 35% of the market. Clearly, the bigger market share exists for cellular hydraulics. Nevertheless, OEMs are additionally shifting in direction of smaller oil sumps with longer oil drain intervals that may impression on the quantity of hydraulics wanted periodically.

Modifications by OEMs additionally impression the formulation of hydraulic oils. As an example, if a smaller sump is used then, the hydraulic oil should now have the ability to cool quicker, transport the identical (or bigger) drive and preserve the meant viscosity of operation whereas being underneath larger stress. In these circumstances, the additive packages involving the antiwear, thermal stability, viscosity index improvers, defoamants and dispersants have to be formulated to work in unison with out compromising the opposite.

There have been adjustments in additive expertise that enable for bigger tolerances for numerous traits however whereas components are evolving, the refining of base oils can also be making an attempt to maintain up. With all of these evolutions, the chemical composition of hydraulic oil in the present day vastly differs from one created within the Fifties. The necessities of hydraulic oil have additionally significantly advanced, forcing these adjustments in formulation.

Hydraulic oils in the present day want to supply longer oil drain intervals, higher stick/slip traits, elevated effectivity, improved conductivity and put on efficiency and an added stage of sustainability. Formulators have to create hydraulic oils that may adhere to those traits whereas additionally not infringing on regulatory necessities. This makes hydraulic oils one of the vital highly effective kinds of oils as a result of they have to conform to those necessities whereas additionally transferring drive from one place to one other.

References

Chevron Lubricants. (2015, January 24). Chevron Lubricants Latin America. Retrieved from Chevron Lubricants: https://latinamerica.chevronlubricants.com

Fitzpatrick, A., & Thom, M. (2021, November 08). How the World Hydraulic Fluid Market Is Altering—And What It Means for the Future. Retrieved from Energy Transmission Engineering: https://www.powertransmission.com/blogs/1-revolutions/publish/189

Mang, T., & Dresel, W. (2007). Lubricants and Lubrication Second Version. Weinheim: WILEY-VCH.

Pirro, D. M., Webster, M., & Daschner, E. (2016). Lubrication Fundamentals, Third Version Revised and Expanded, ExxonMobil. Boca Raton: CRC Press, Taylor & Francis Group.