The speed at which know-how evolves is rising. Gone are the times of developments taking a decade-plus to develop. In some cases, know-how can develop into outdated in a matter of years, perhaps even months. Consider a smartphone. The newest gadgets have built-in synthetic intelligence and augmented actuality options that the typical particular person had barely thought of some years in the past.

Hydrodemolition tools isn’t any exception. As a substitute of going towards jackhammers and hand lances, concrete contractors are competing towards the newest hydrodemolition evolutions. Outdated machines can nonetheless outperform handheld tools, however new hydrodemolition know-how gives important developments. Current options present superior ends in much less time, finally giving concrete contractors who spend money on new know-how a step forward in progress, innovation, and challenge outcomes.

Whereas older fashions nonetheless run and are quicker and simpler than handheld instruments, new hydrodemolition know-how gives way more performance.Aquajet

Whereas older fashions nonetheless run and are quicker and simpler than handheld instruments, new hydrodemolition know-how gives way more performance.Aquajet

Consumer Friendliness

Many contractors fear about making the leap to new know-how, however with user-friendly options and an intuitive design, as we speak’s hydrodemolition robots are simpler than ever to function. Devoted assist and coaching are additionally out there to make sure the whole crew feels assured and succesful. Older machines, which have fewer automated capabilities, are inclined to require extra operator expertise and intuitive understanding to initially get the settings proper. Fashionable machines’ settings paired with a supportive producer make it far simpler for an operator with primary coaching to confidently run tools.

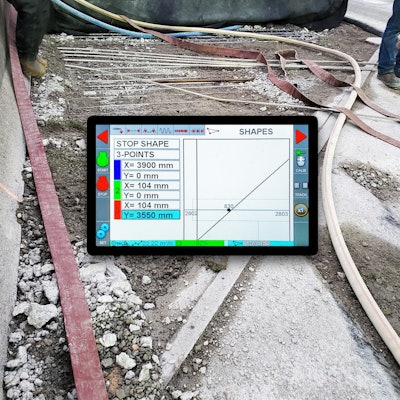

With a state-of-the-art working system, customers can set parameters tailor-made to the specs wherein they should take away concrete and save these presets for future use. Storing these parameters additionally offers a great level of reference for reviewing the machine’s manufacturing after a job and the place potential changes might be made. Ought to the machine’s parameters require any tweaks, it may be so simple as fine-tuning the settings. With older techniques, some modifications required an operator with intensive data and years of expertise to know the way to make small, nonspecific changes.

Some new machines additionally enable customers to say goodbye to manually preserving upkeep logs. These machines current clear, easy-to-understand error messages ought to an issue happen, slashing potential troubleshooting time.

Implementing any change to an tools fleet could have a studying curve, however fortunately, fashionable know-how is designed to make the transition as seamless as doable. With user-friendly interfaces, preset parameters, and simply accessible coaching supplies, contractors and their groups can rapidly adapt, turning the problem into a possibility for progress and growth.

Upgraded Lance Techniques

For many of the hydrodemolition business’s 30-plus years, merely with the ability to execute hydrodemolition was sufficient to qualify as “leading edge.” Controlling a water jet by mechanical means was a safer, quicker, extra refined option to take away concrete in comparison with a jackhammer or hand lance.

Pretty not too long ago, producers launched robots with a brand new lance motion to the market harnessing the advantages of each the oscillating and rotating lance actions. The result’s a water jet that strikes again to entrance and proper to left. If the lance was holding a pen somewhat than taking pictures water, it could create a determine 8, or infinity, sample.

The infinity sample creates fixed oscillation pace that ends in higher manufacturing. Moreover, it creates a tough however even consequence and nearly eliminates pipe holes, forsaking the perfect bonding floor. Creating the right profile for superior bonding power ends in repairs that may last as long as 3 times longer. This may please challenge engineers and forestall the job from being held up by subpar outcomes.

If the challenge additionally presents difficult shapes or angles, akin to a bridge with a joint at a 45-degree angle, operators can set new machines to chop in a wide range of shapes. So, the triangle form leftover from a bridge joint now not must be eliminated manually by jackhammers or hand lances.Aquajet

If the challenge additionally presents difficult shapes or angles, akin to a bridge with a joint at a 45-degree angle, operators can set new machines to chop in a wide range of shapes. So, the triangle form leftover from a bridge joint now not must be eliminated manually by jackhammers or hand lances.Aquajet

When an operation implements a machine that makes use of the infinity sample, they’re making probably the most environment friendly use of all of the power at their disposal. Contractors utilizing tools with an infinity sample will usually enhance effectivity by 15-20%, relying on the scope of the work. (This might enhance to 50% with the right settings and relying on which settings are modified.)

This lance system improve represents state-of-the-art engineering with precision and management beforehand thought unattainable. Contractors and their crews can take satisfaction in realizing they’re utilizing one of the vital superior, environment friendly, and highly effective instruments out there to set a brand new customary of their business.

Superior Parts

Fashionable hydrodemolition machine elements have extra performance for improved efficiency. For instance, as we speak’s hydrodemolition robots have a sensor of their hoist system to set the peak of the hood, eliminating the necessity for operators to manually examine. Whereas some might imagine extra parts enhance the probability of breakdowns, that isn’t the case. Parts in new machines are designed to final and require much less consideration. For instance, rollers needed to be tightened day by day on previous machines. In the present day’s rollers are spring-tensioned with absolute sensors that simply regulate by way of a button, are wider to enhance stability, are preset, and are way more sturdy. All these assist to permit operators to strategy them with a set-it-and-forget-it mentality.

In the present day’s hydrodemolition robots are state-of-the-art, meticulously engineered machines with improved elements and a wide range of equipment. They supply immense enhancements to productiveness and ease of operation.Aquajet

In the present day’s hydrodemolition robots are state-of-the-art, meticulously engineered machines with improved elements and a wide range of equipment. They supply immense enhancements to productiveness and ease of operation.Aquajet

Talking of tracks — these can influence a challenge’s high quality and effectivity. Take a bridge job, as an example. Typically, operators must drive the machine as much as a couple-hundred ft to the work space. New monitor techniques enable the robotic to now journey 50 m per minute versus 30 m/m with an older machine. The trendy monitor techniques additionally present a smoother experience, decreasing put on on the machine, and elevated stability throughout operation.

Adopting new know-how looks as if a big step, nevertheless it’s essential to think about the long-term advantages of lowered upkeep prices, extra dependable tools, quicker challenge turnaround instances, and a better path to profitability.

Optimum Outcomes

In case you nonetheless have equipment that performs adequately, investing in new tools can appear pointless. Hydrodemolition contractors, nonetheless, aren’t competing with jackhammers and hand instruments anymore. They’re going up towards the newest options which might be quickly advancing. Those that make investments to supply higher ends in a faster, simpler method take the lead. Concrete contractors who undertake the newest know-how aren’t simply investing in a machine, they’re investing of their firm’s future.