The demand for heavy gear and off-highway (HE/OH) automobiles is rising. Heavy-duty equipment like agricultural tractors, excavators and haul vans are vital for a lot of industries and the sourcing of the uncooked supplies wanted to fabricate quite a lot of client and industrial tech merchandise. The necessity for these automobiles is growing as international city populations rise and industrial prospects and shoppers demand better capabilities in varied merchandise.

In the meantime, new rules and sustainability mandates require corporations in all industries change into extra environment friendly, engaging in better productiveness whereas utilizing much less power and sources. Heavy gear and off-highway unique gear producers (OEMs) should innovate, delivering automobiles and gear which can be smarter, extra related and extra environment friendly. Historically hydromechanical methods are being changed with superior software program and electronics that may help core capabilities whereas additionally offering a platform for extra superior options and performance now and sooner or later.

The following technology of heavy gear and off-highway automobiles would be the most advanced ever. Conventional approaches to automobile improvement, manufacturing, and repair is not going to scale to satisfy the calls for of those automobiles, driving heavy gear and off-highway OEMs to hunt new strategies that align with the rising want for innovation, agility and pace.

Enterprise, tech tendencies for HE/OH producers

There are a couple of challenges for HE/OH producers as they navigate this business. Along with the transition towards software-defined merchandise, HE/OH merchandise should change into extra environment friendly and sustainable to satisfy varied rules and environmental targets. And whereas the necessity for innovation is excessive, producers have to be cautious to maintain tempo with out overspending on applications that won’t ship near-term worth.

HE/OH producers are also investing in electrification and autonomous driving and robotics to attain a way forward for sensible, environment friendly and high-value merchandise. From a enterprise perspective, these identical progressive capabilities can present alternatives to create new value-based enterprise fashions that generate extra steady high-margin income.

Electrification, Various Fuels Drive Beneficial properties in Effectivity

Heavy gear and off-highway industries are exploring electrification as a method of bettering gear effectivity and business sustainability. Electrified powertrains, whether or not they’re full battery electrical or hybrid diesel-electric, have proven potential in a number of functions widespread to the HE/OH industries.

Battery electrical automobiles (EVs) are already being deployed in high-load and low-range functions and in smaller automobiles like skid steers and small excavators. These functions are well-suited to the excessive torque and precision of electrical motors. In addition they take pleasure in further advantages of lowered noise, vibration and emissions producing a more healthy and extra nice job website. Lengthy-term price of operation and possession of those automobiles is usually decrease than their diesel counterparts.

Electrical energy supply has additionally elevated in viability because of enhancements within the practices of HE/OH prospects. Within the agricultural sector, many farmers are decreasing or eliminating soil tilling as part of their rising practices, opting as an alternative for direct seed drilling or minimal tillage approaches. By minimizing or eliminating the ploughing course of, the typical energy required to sow a discipline is lowered. This discount in common energy demand signifies that battery-powered automobiles can function longer on a single cost, making certain the farmer can sustain with tight planting and harvesting schedules.

Many HE/OH OEMs are also growing gear that may be powered by hydrogen and different various gas sorts. These fuels can scale back combustion emissions and the general carbon footprint of automobiles with out imposing lengthy refueling occasions. These various power sources additionally provide completely different vary and cargo traits, making them well-suited to completely different functions to battery EVs.

Some challenges stop battery electrical and various fuels from being a scalable answer within the near-term for all segments and functions. Charging time is probably the most salient downside, significantly for distant job websites the place high-quality, fast-charging connections are doubtless not obtainable. Electrification additionally tends to extend the upfront price of equipment. On the identical time, dependable provide of different fuels stays a hurdle as a result of fueling infrastructure and provide chains for various fuels is nascent.

Automation’s Future Function in Self-driving, Autonomous Robotics

In the long run, heavy gear and off-highway OEMs are specializing in the event of autonomous driving and robotics for farming, development, mining and different heavy-duty functions. The event of an autonomous machine that may independently navigate and manipulate its surroundings is advanced, requiring built-in methods of sensors, on board and cloud computing and exact actuation.

These machines face different distinctive challenges. Because of the low manufacturing volumes widespread to the business, the price of customized sensors and laptop chips is tougher to recoup. Consequently, HE/OH OEMs usually depends on off-the-shelf sensor and compute elements to allow autonomous performance, which locations further constraints on engineering and design.

Autonomous machines additionally could require better object recognition skills to that of a self-driving automobile. An autonomous sprayer, for instance, would wish to have the ability to distinguish between crops, dangerous weeds and different non-crop vegetation that could be useful.

These OEMs, nevertheless, have the benefit of working in comparatively managed environments, not less than in comparison with dense city environments or highways stuffed with different drivers. An autonomous tractor or haul truck, for instance, will solely ever function inside a restricted space, corresponding to a crop discipline or quarry, which makes routing and navigation less complicated. Even when transferring to a brand new discipline or job website, these comparatively small areas could be digitally mapped intimately, offering the autonomous system with correct topological info to information routing and navigation. With managed, predictable routes, human operators’ security is simpler to make sure.

Electrification, automation and the underlying shift towards software-defined automobiles and equipment are also being pursued in response to buyer and regulatory calls for, and to capitalize on new enterprise alternatives. Incorporating and scaling these applied sciences is dependent upon the power of corporations to handle price, overcome complexity in improvement and produce dependable and sturdy methods.

Digitalization as Basis for the Future

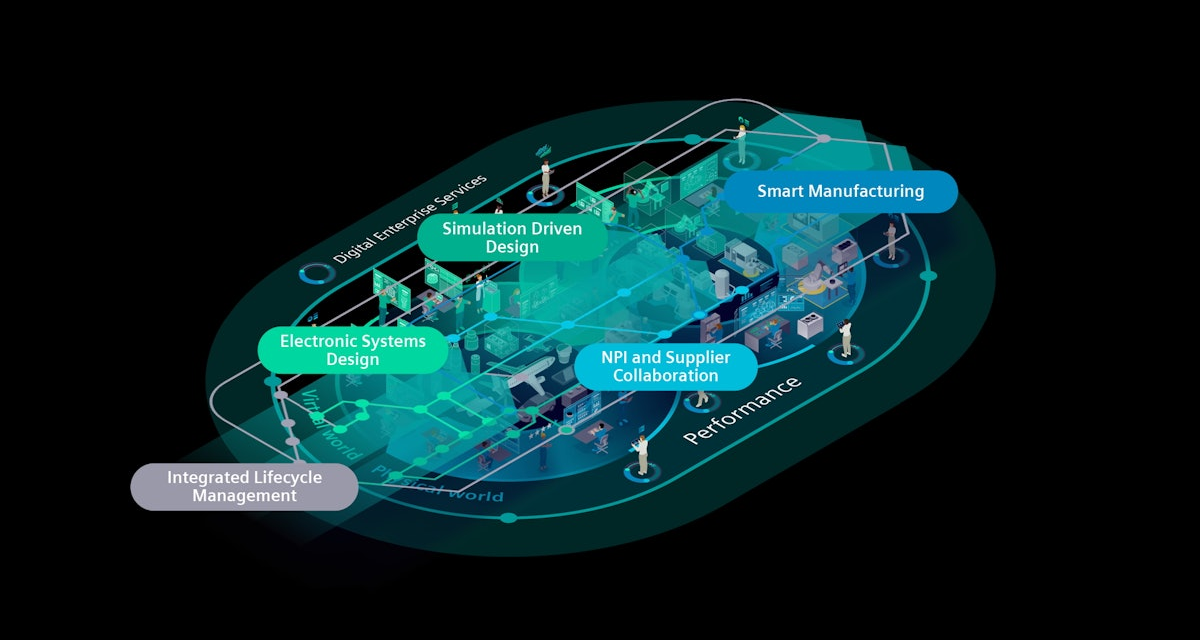

Digital transformation of your complete lifecycle from design and engineering via to in-field service and upkeep may also help OEMs design, produce and repair the related, sensible, and dependable HE/OH automobiles and gear their prospects want.

By the digital twin, HE/OH automobile producers can drive engineering actions that span a number of disciplines, domains and even lifecycle phases. Such an strategy incorporates software program, electrical, digital and community domains right into a holistic system-level improvement program. Necessities for the automobile’s mechanical, electrical, digital, community and software program methods could be outlined and built-in on the earliest phases of improvement, making certain domains are synced from the start.

As improvement progresses, the digital twin ensures engineering information stays in-sync and is accessible the place and when it’s wanted, stopping miscommunications and guaranteeing selections are made based mostly on the newest info.

Superior simulation instruments additionally facilitate steady verification and validation, selling the optimum steadiness of a number of features of auto efficiency. When utilized in automated eventualities, simulation can be utilized for design exploration, algorithmic decision-making, or to nearly execute a large variety of responsibility cycles for the certification of autonomous methods.

Digitalization may also prolong into the manufacturing and repair lifecycle for HE/OH automobiles, serving to develop sensible and versatile manufacturing methods and grasp mixed-model manufacturing in a posh international manufacturing ecosystem. HE/OH automobiles are both extremely personalized and even distinctive; usually about 20 p.c of the ultimate configuration of a automobile is restricted to the shopper. The digital twin helps corporations create versatile and adaptable manufacturing methods that accommodate these distinctive configurations whereas sustaining excessive throughput.

The great digital twin additionally helps a closed loop between design, manufacturing and the product in use the place information from all through the lifecycle could be captured and become worth for the OEM and their prospects. Manufacturing information, corresponding to high quality reviews or scrap charges, and real-world product efficiency information could be leveraged to enhance product designs and manufacturing methods. Critically, real-world information can be used to offer high-quality customer support and technical help as OEMs transition from machine distributors into answer companions.

By capturing reside operational information, OEMs can present prospects with focused and environment friendly prognosis and restore companies and even assist stop unscheduled downtime by anticipating points and recommending interventions earlier than they take a machine out of service. These capabilities will solely change into extra vital in a way forward for automated automobiles and equipment, as sturdy operational information could be analyzed with industrial synthetic intelligence (AI) to information the event of recent software program options and enhance machine efficiency.

Digitally Establishing the Merchandise of the Future

Innovation within the HE/OH business is being pursued to develop capabilities that can help development, farming, mining and materials dealing with sectors in a future during which effectivity, sustainability and productiveness have to be addressed concurrently. As pressures mount, these corporations want to rework for the longer term and enabling progressive designs in an business characterised by low volumes, small margins and demanding functions.

The great digital twin will act as the muse for the collaborative, built-in strategy demanded by trendy automobiles, bringing the mechanical, electrical, digital and software program domains collectively to design a whole system. Along with bettering information sharing between all stakeholders, the excellent digital twin facilitates the interpretation of that information into actionable insights that may assist scale back cycle occasions, improve effectivity and enhance market agility. The result’s a definite aggressive benefit in assembly rising buyer calls for for better efficiency and smarter options whereas additionally serving to to beat the challenges of rising complexity, shifting workforces and the necessity for sustainable designs for HE/OH automobiles.